From Paper Trails to AI

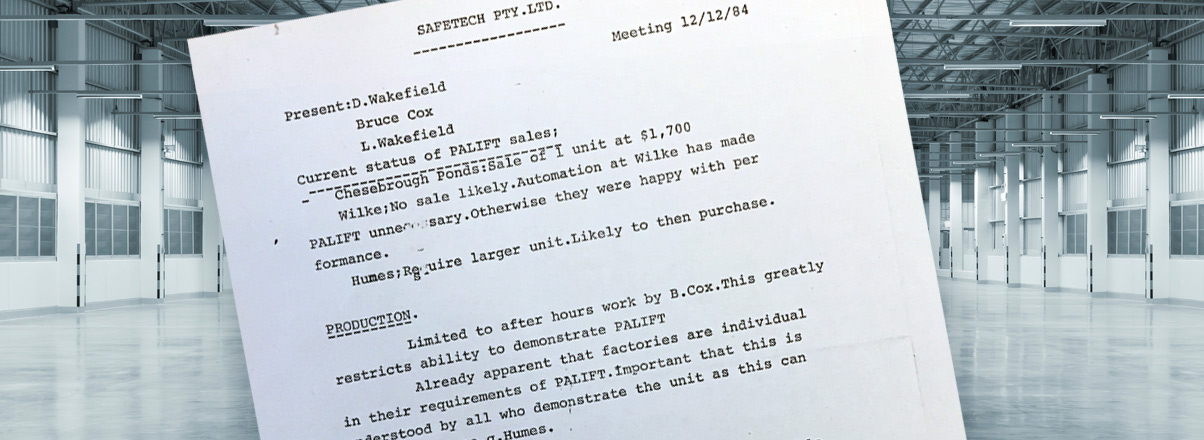

Back in 1984, Palift’s first meeting minutes recorded the early production highs and lows of Safetech’s maiden product: the Palift Pallet Leveller. Typed, highlighted and photocopied, these notes outlined action plans, passed through departments and eventually disappeared into filing cabinets, their contents remembered only by a few.

Back then, orders arrived by post and hand-drawn engineering diagrams shaped production. Paper overflowed on desks and staying organised was a skill in itself.

The digital era brought spreadsheets, manual data entry, basic CAD software and email – transforming how Safetech worked and what to build.

.jpg)

Today, Safetech faces new manufacturing demands and our evolution continues. AI tools now assist with error detection, safer product design and project scheduling across multiple facilities.

From handwritten plans to intelligent automation, the Safetech journey reflects more than technological change – it is a culture of adaptation and resilience that enables custom manufacturing to push forward one innovation at a time.

.jpg)